The K40 laser cutter, if you know about it, comes with absolutely the bare minimum to get you started. Fortunately, it does comes with a cooling solution: You supply your own water bucket, fill it with distilled water, and drop in the supplied water pump. Failure to do that will probably result in a burnt out laser tube.

As you can probably imagine: this is not a super good system – the system is open-air, and is therefore easy to get contaminated. In my case, my coolant reached questionable consistency (that is, gooey) after a couple of month. So I swapped out the “supply-your-own-bucket” cooling system for a “amazon-cheap-pc-water-cooling” system.

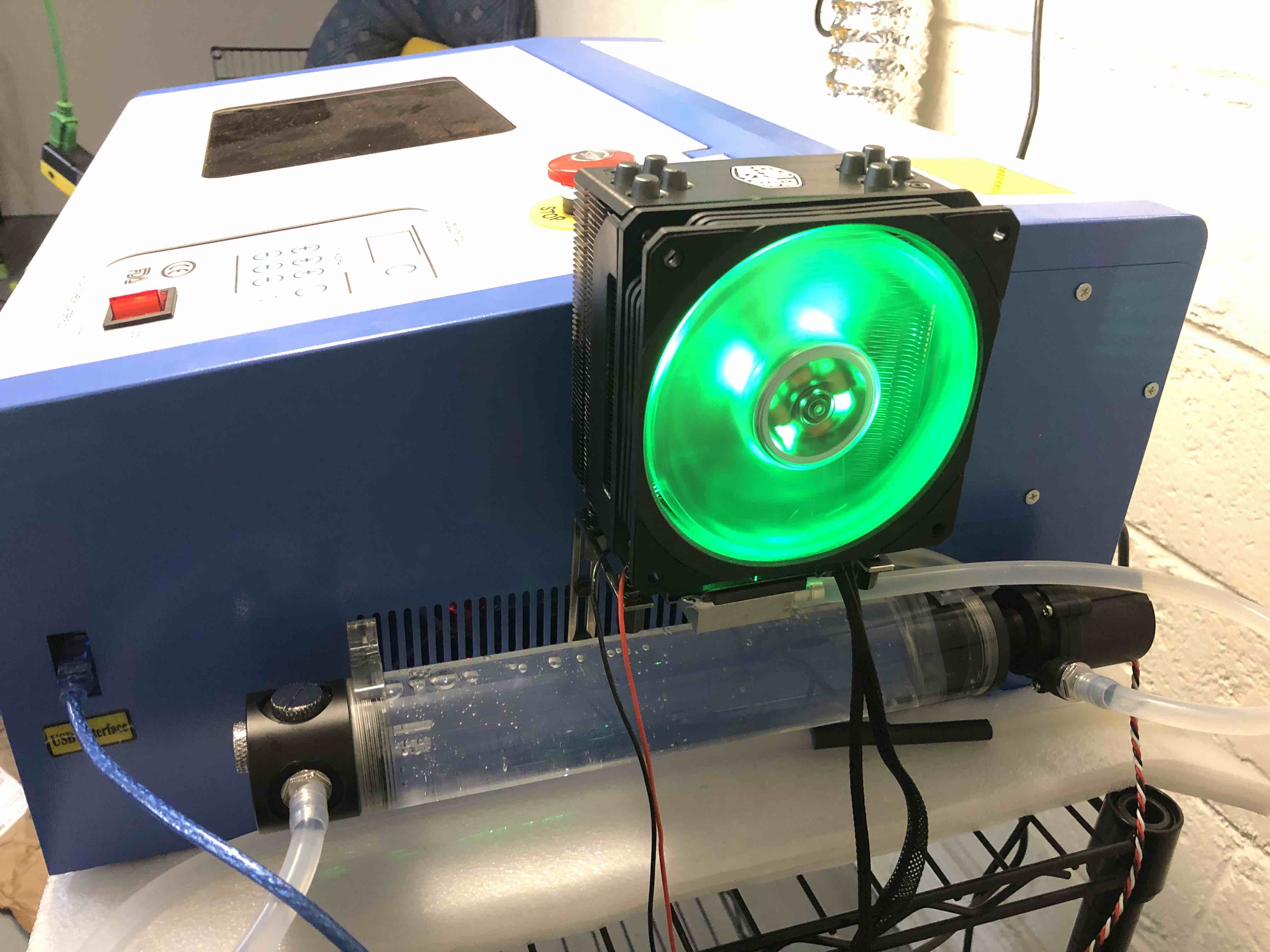

The system is simple and consisted of 5 parts:

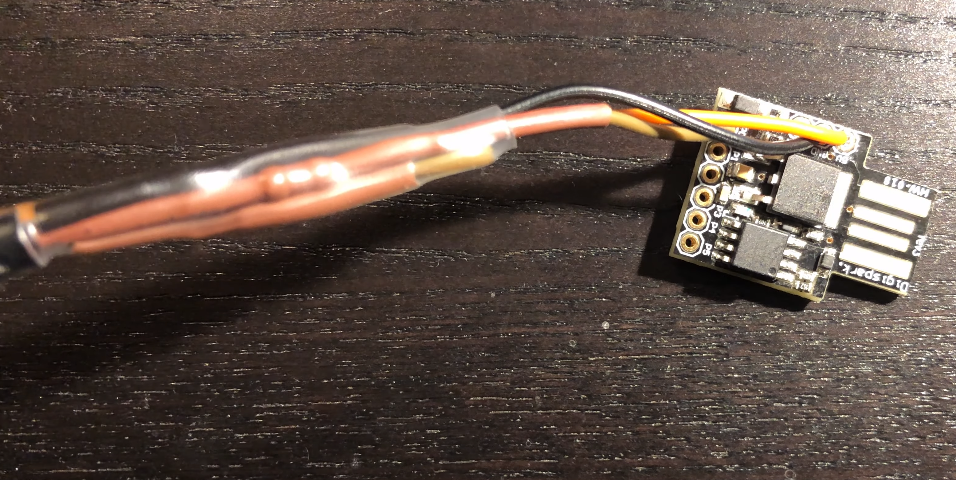

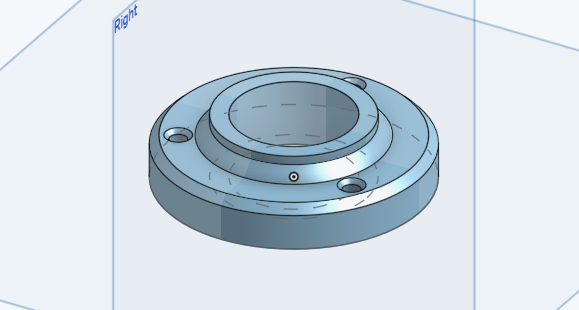

- a off-the-shelf PC water-cooling pump / reservoir combo

- a peltier cooler

- a water-cooling heat-exchanger

- a CPU cooler

- a PC power supply

The pump feeds water into a heat-exchanger, where heat gets extracted by the peltier cooler into the CPU cooler, then into the laser tube and back into the reservoir.

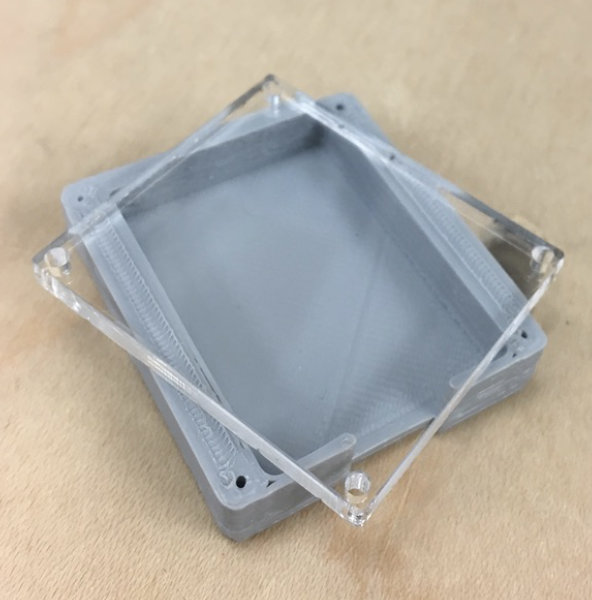

Everything got mounted on to the side of the machine. It looks reasonably good.

I hope this results in lower machine maintenance in the future.